Steelmaking Which of the following is NOT a source of steel scrap? Try again! Next Question Test your Understanding of. Steelmaking EAF is a primary steel making process and stands for what? Steelmaking True or False: used steel CANNOT be recycled in the steel-making process. Steelmaking BOF is a primary steel making process and stands for what? Course Dashboard Reibus U Close the quiz Close the quiz Test your Understanding of. Steel Foundations Certificate of Completion Earn your Certificate of Completion by taking the quiz after each module, and scoring 80% or higher. Typically, the steel delivered by the BOF still does not meet the customer’s metallurgical specifications, so it requires additional refinement in a secondary metallurgical station and/or a vacuum degasser prior to moving on to the next process.

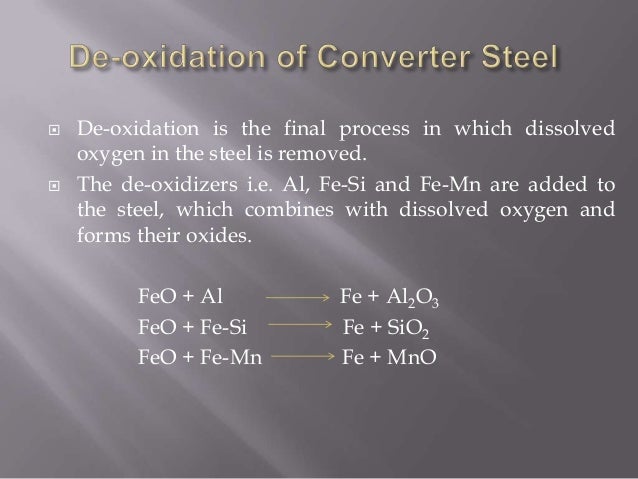

Most steel producing mills increase efficiency by having two BOF vessels, so they can rotate being loaded and blown down with oxygen. The vessel is now ready for the next load of material. Then, the vessel is rotated back in the opposite direction to pour out and discard the slag along with all the detrimental impurities it absorbed. Flat Products: The steel is cast into slabs, which are then. Once the carbon level has been sufficiently reduced in the steel, the lance is removed, and the vessel is tapped, or emptied, by rotating it to pour the refined steel into a ladle. The hot metal is converted into steel through a steelmaking process called the LD process. The BOF process reduces the carbon via oxidation from 4.0% to approximately 0.04%. The CO2 is expelled as gas, while the SiO2 and other impurities are absorbed into waste matter, called slag, created from the burnt lime addition. In addition to mixing the materials in the converter, the oxygen reacts with the silicon and carbon dissolved in the hot metal, generating heat, carbon dioxide (CO2), silicon dioxide (SiO2), and other impurities. Next, pure oxygen is blown into the mixture using a water-cooled metal tube called a lance. In this process, either hot metal or pig iron, steel scrap, and flux (burnt lime) are charged, or loaded, into a furnace commonly called a converter or vessel. LD Process of Steel Making (BOS) has been explained in this video with following key topics : Principles of oxygen steel making process Constructional deta. It was originally developed in the early 1950s in the Austrian cities Linz and Donawitz, which is why it can also be referred to as the LD process. The basic oxygen furnace (BOF) process is a method of primary steelmaking in which carbon-rich hot metal or pig iron, produced by a blast furnace, is made into steel. The Basic Oxygen Furnace Steel Foundations In the original LD process, oxygen was blown over the top of the molten iron through the water-cooled nozzle of a vertical lance. Play 0:58 Sorry, your browser doesn't support embedded videos.

0 kommentar(er)

0 kommentar(er)